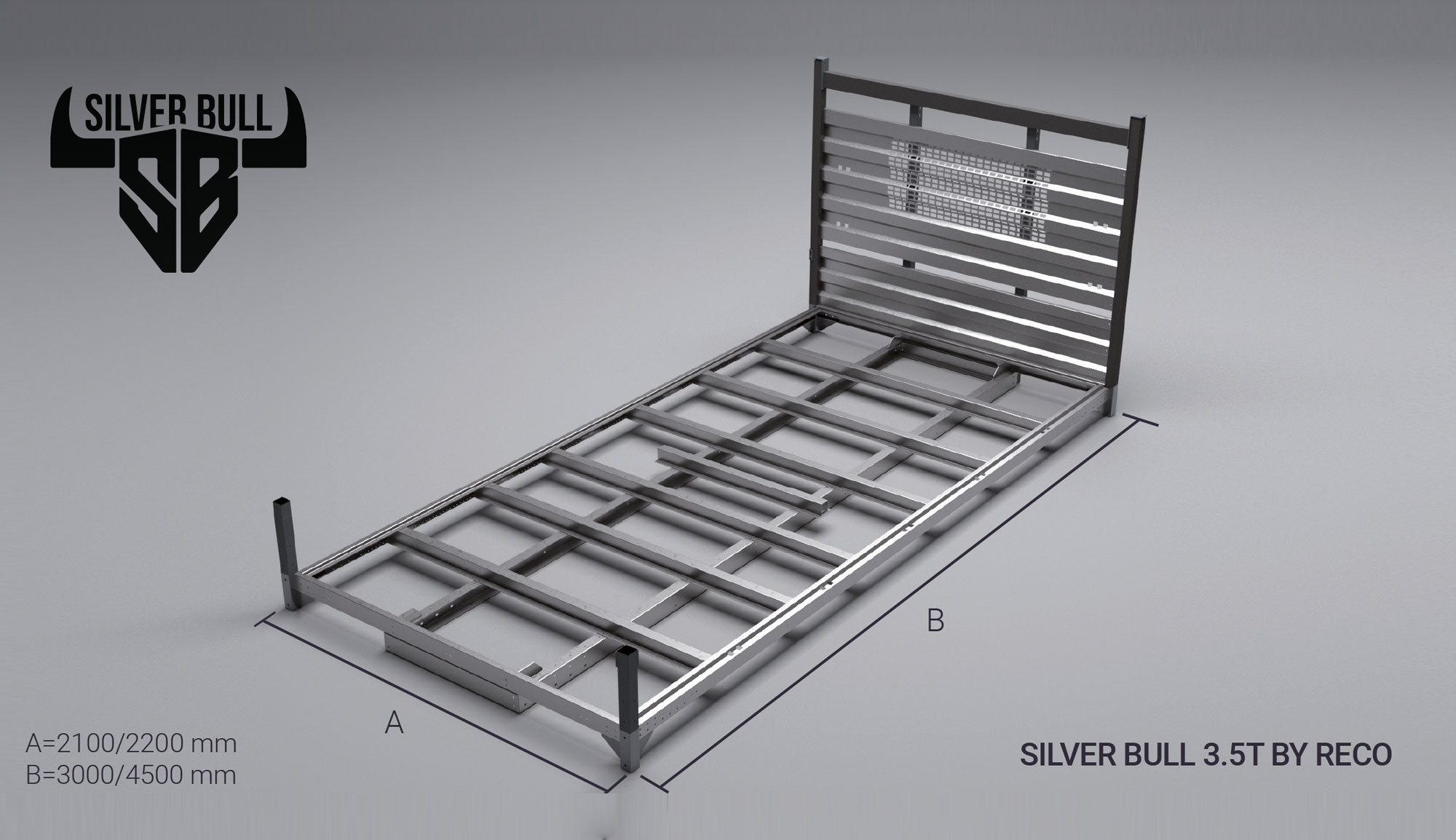

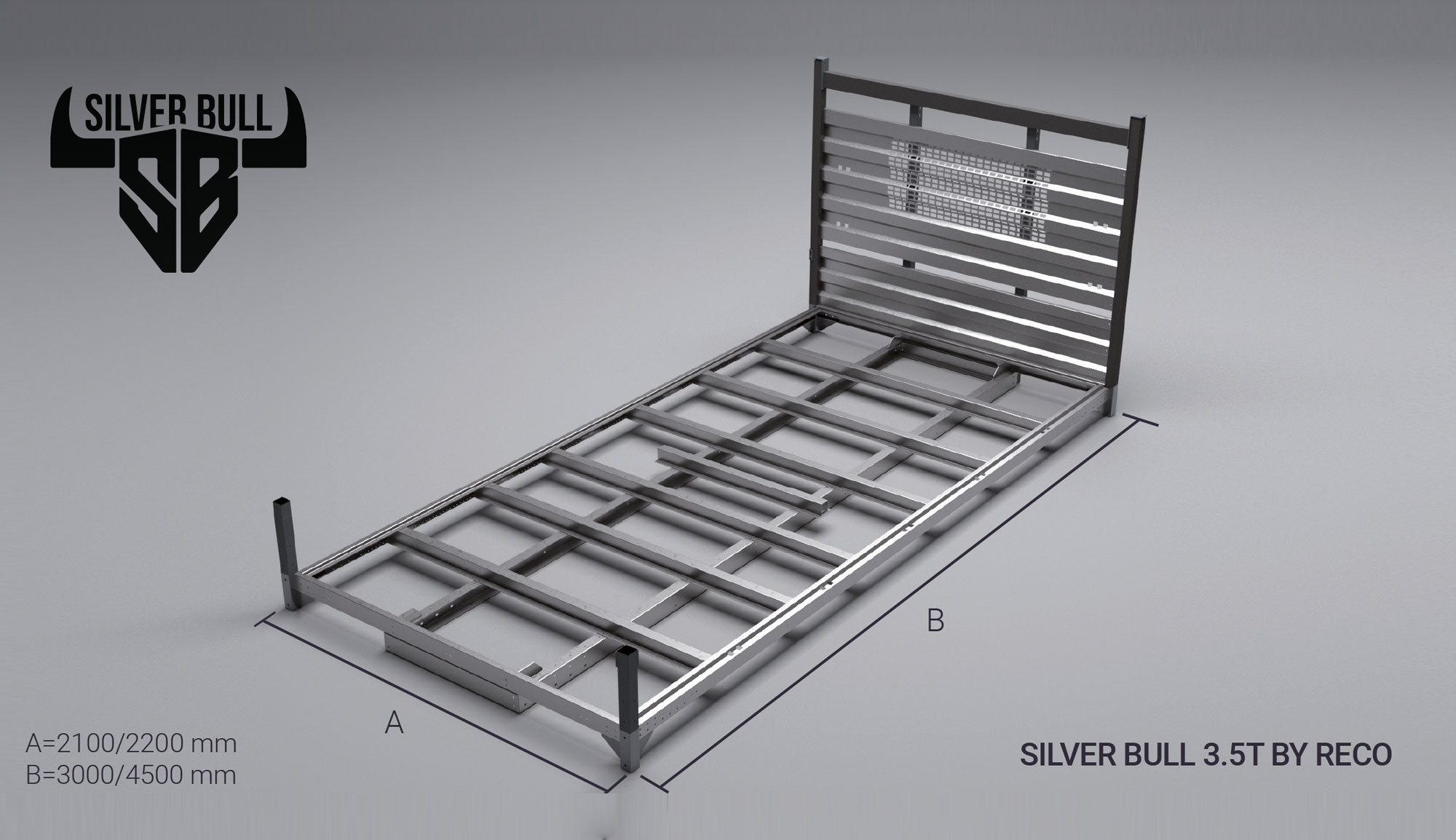

Discover the hidden power behind a traditional 3.5T dropside truck: Reco technology.

Meticulous material study and selection, combined with effective product engineering, have given birth to an innovative kit with 4 patented features.

This is a true performance multiplier, capable of exponentially boost the productivity and competitiveness of the truck bodybuilder while drastically reduce processing costs.

Record-breaking assembly, unbeatable efficiency

With the Silver Bull 3.5T kit, the assembly time for a fixed dropside is reduced by 70% compared to the average: Just two people can assemble the complete unit in only 4 hours!

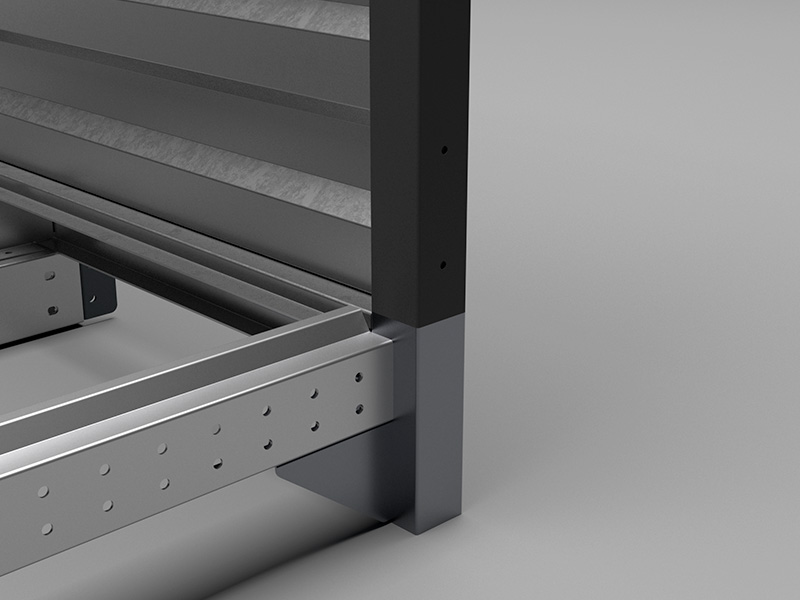

The self-centering system of the cargo box frame, along with complete pre-drilling of the profi les, allows for quick assembly and eliminates any margin of error.

This enables the entire setup to be completed even by unskilled personnel. Silver Bull, in fact, is assembled with basic tools and requires no welding.

Additionally, Silver Bull is a universal kit that fits any model and make of vehicle up to 3.5T. A real abracadabra for the truck bodybuilder!

Magnelis® S355: Unmatched Durability

Another major advantage of Silver Bull is its structure made of Magnelis® S355, a high-strength steel with an innovative automotive-level finish.

Thanks to its specific composition with a high percentage of magnesium, it offers astonishing resistance to oxidizing agents with self-healing properties and requires no additional surface treatment.

FEATURES THAT MAKE THIS PRODUCT UNIQUE:

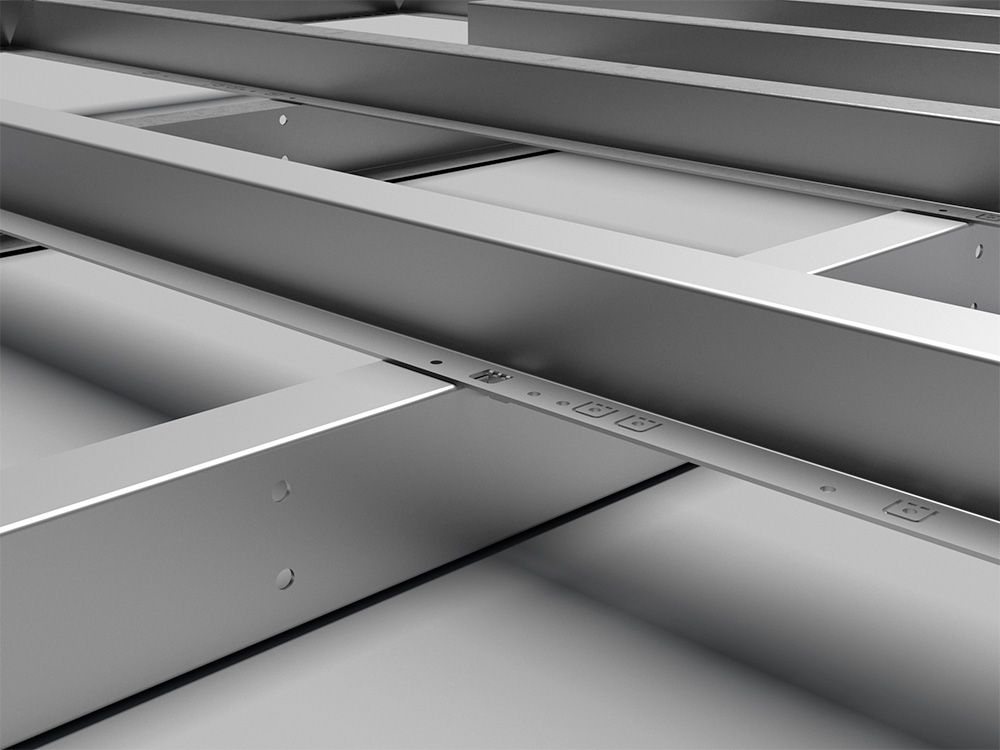

Patented Cross Beam Self-Centering System

Thanks to this innovative system, the cross beams can be positioned correctly without the need for measurements. The cross beam also serves as a template for precise drilling of the subframe, ensuring quick and accurate installation.

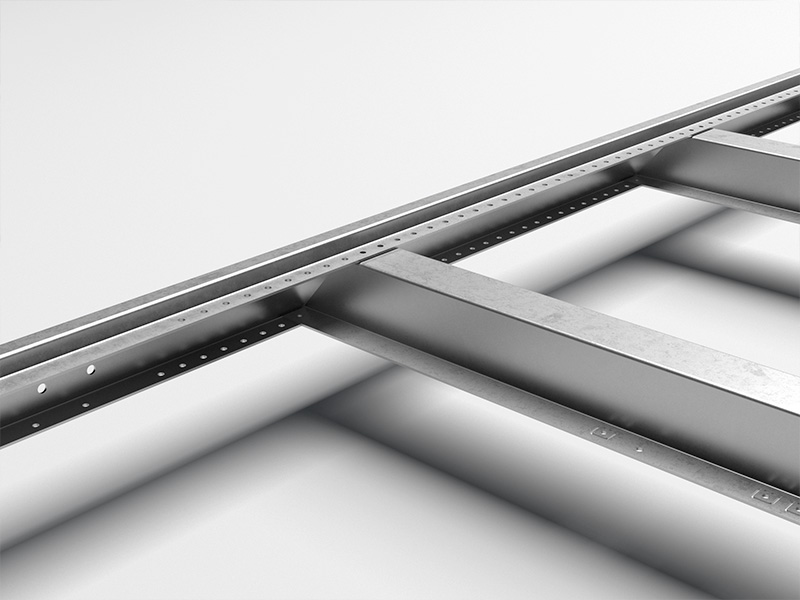

Pre-Drilled frame profiles and Cross Beams

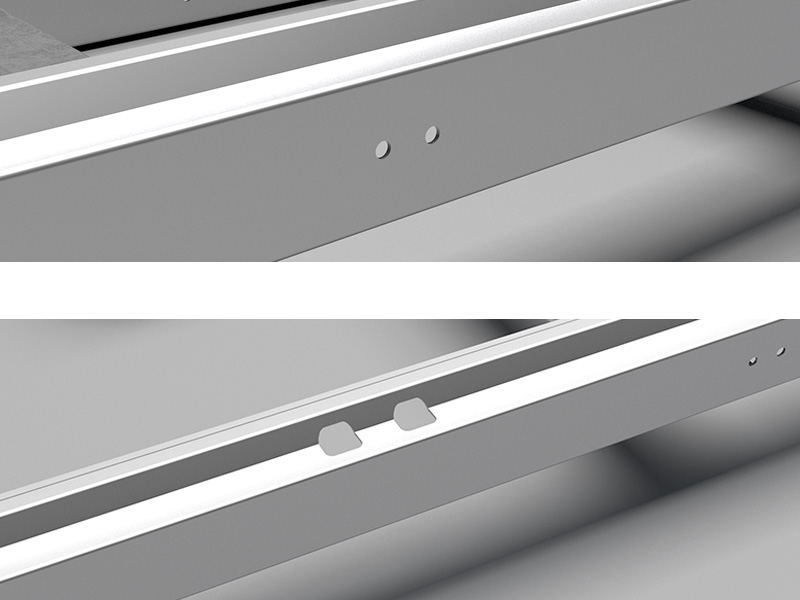

The pre-drilling of the frame profiles and cross beams allows for quick and efficient assembly of the structure, intercon- nected through rivets. The modular system ensures perfect compatibility with any configuration of plywood panels that make up the loading platform. Each cross beam has a 45° contour that allows for the convenient installation of hinges before the structure is assembled, enabling it to slide within the frame profiles and be fixed at the desired point.

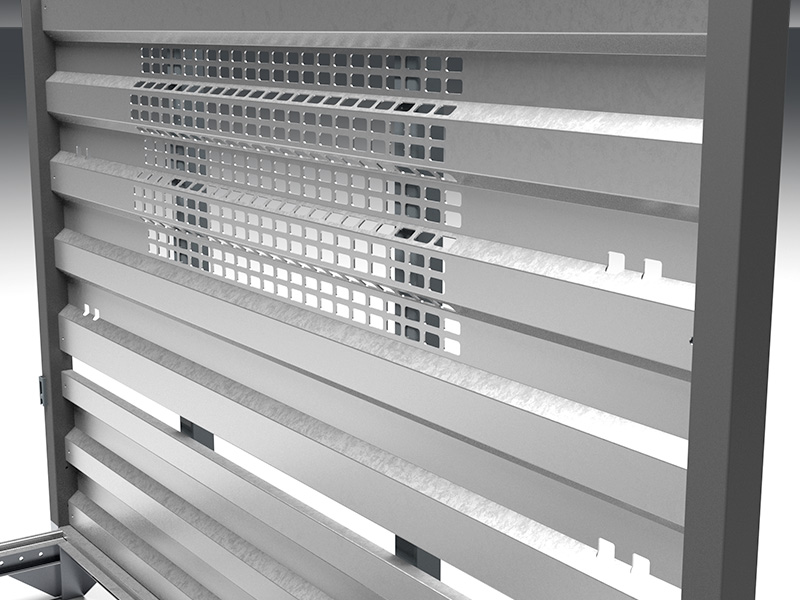

Pre-Drilled profiles for Hinges and Load Straps

The frame profiles feature pre-drilling for hinge installation, as well as slots for securing load straps, making the assembly process simple and fast.

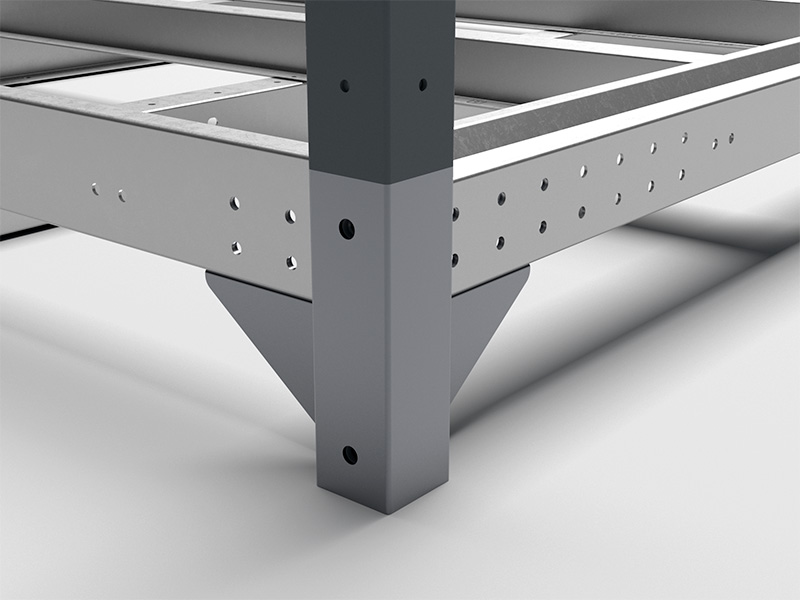

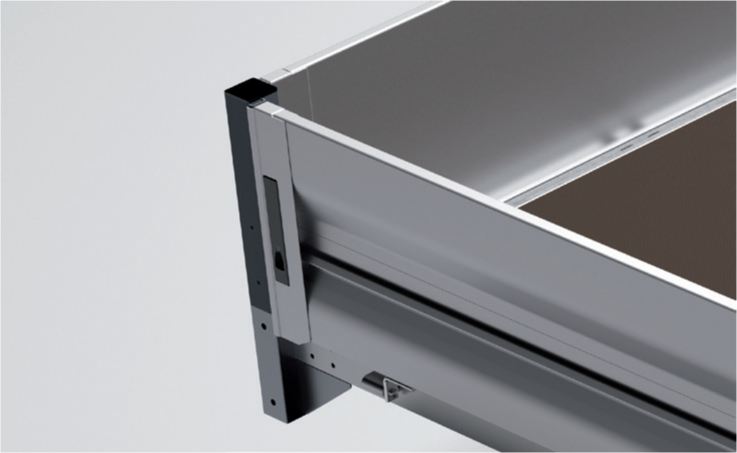

Stainless Steel Corner Bracket

The stainless steel corner bracket is the cornerstone of the entire structure, providing great stability and serving as a connection point for longitudinal beams and stakes. Its robustness ensures a durable and reliable structure.

SILVER BULL: INNOVATION AND EFFICIENCY UP TO 3.5T

Modularity

Silver Bull is adjustable in length with increments of 100mm. The cutting of Magnelis® elements requires no additional interventions, thanks to the self-healing properties of the material.

Front Rack

Silver Bull includes a robust front rack made of steel, coated with a cataphoretic treatment and powder coating, performed according to the highest Automotive standards. This guarantees durability and resistance to weather conditions.

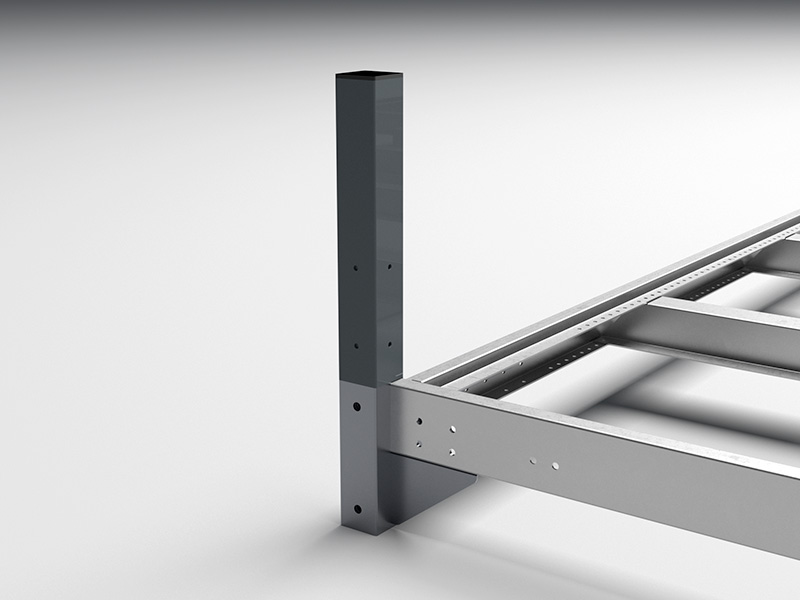

Pillars

The steel pillars, with cataphoretic treatment and powder coating, are equipped with the matching element for aluminium uprights.

Front Wall

Silver Bull’s front wall is made with a robust Magnelis® sheet. A light version is also available, consisting of three aluminium profiles to be screwed onto the steel frame of the front wall, offering options for different weight and strength requirements.

ALUMINUM DROPSIDES

Silver Bull includes tailor-made anodized aluminum dropsides, cut at length and equipped with pre-assembled hinges and aluminium locks.

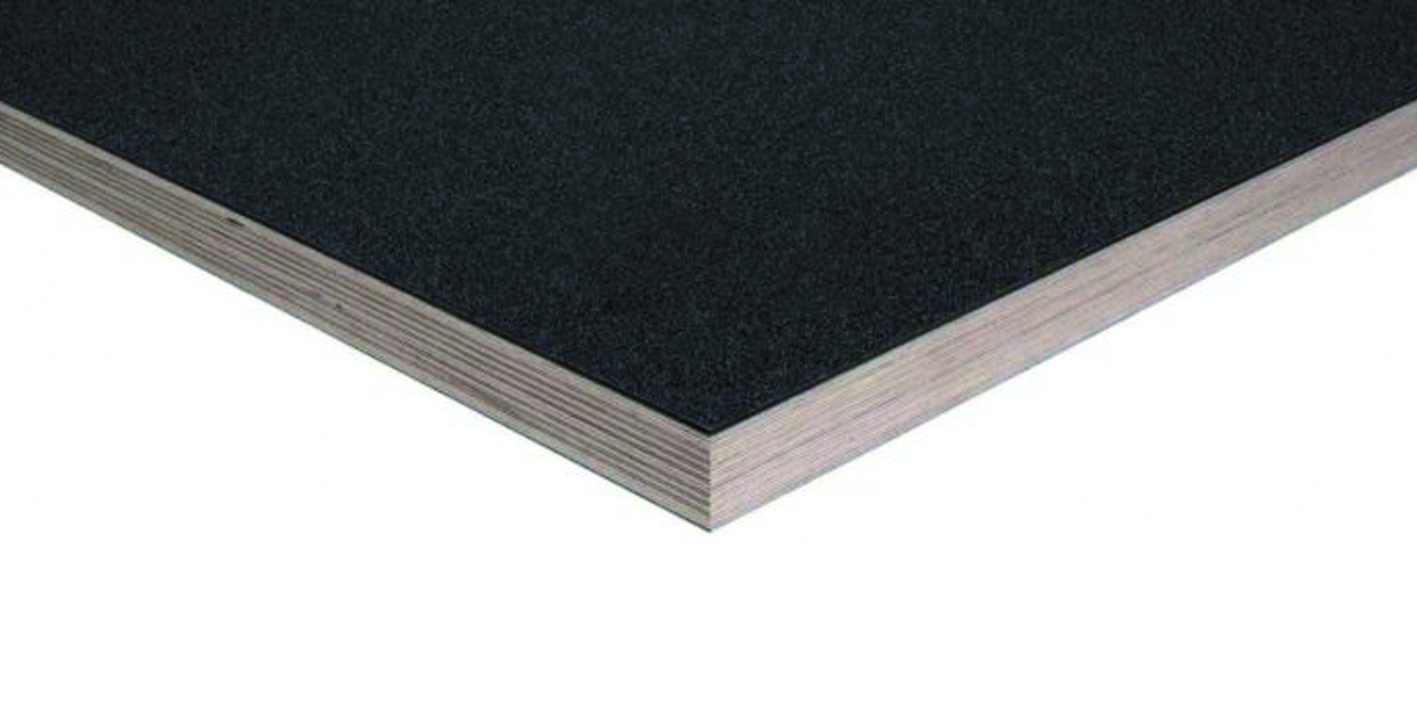

Birch plywood floor

Silverbull’s floor features top quality 100% birch plywood panels with outstanding mechanical properties.